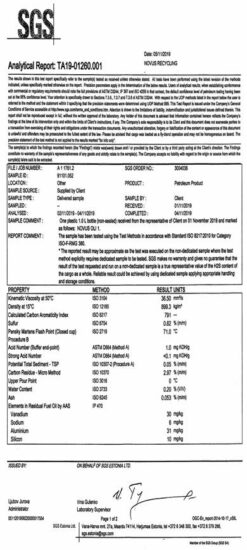

Technology successfully tested and used 2017-2020 in Europe and UAE port.

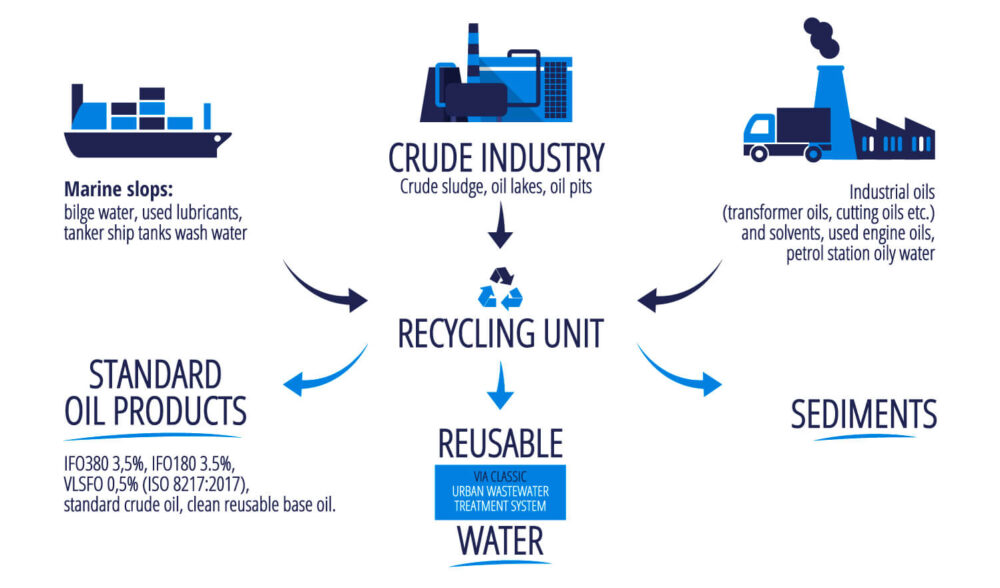

Recycling of marine slops,

crude sludge and used oils

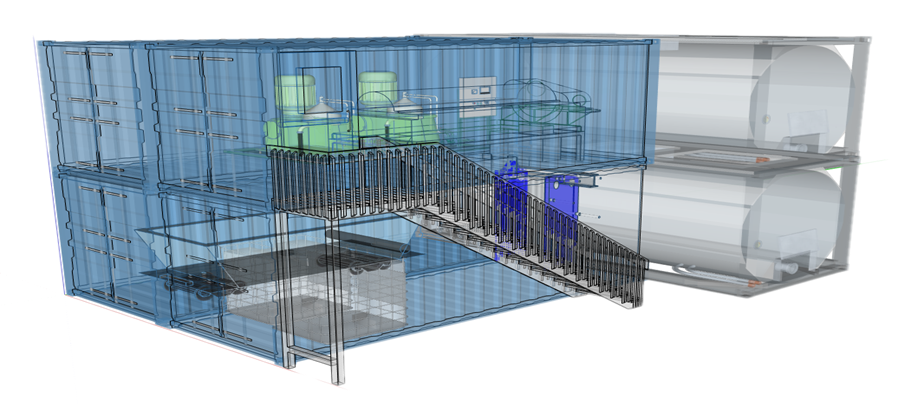

Recycling of marine slops, crude sludge and used lubricating oils

RECYCLING SOLUTIONS

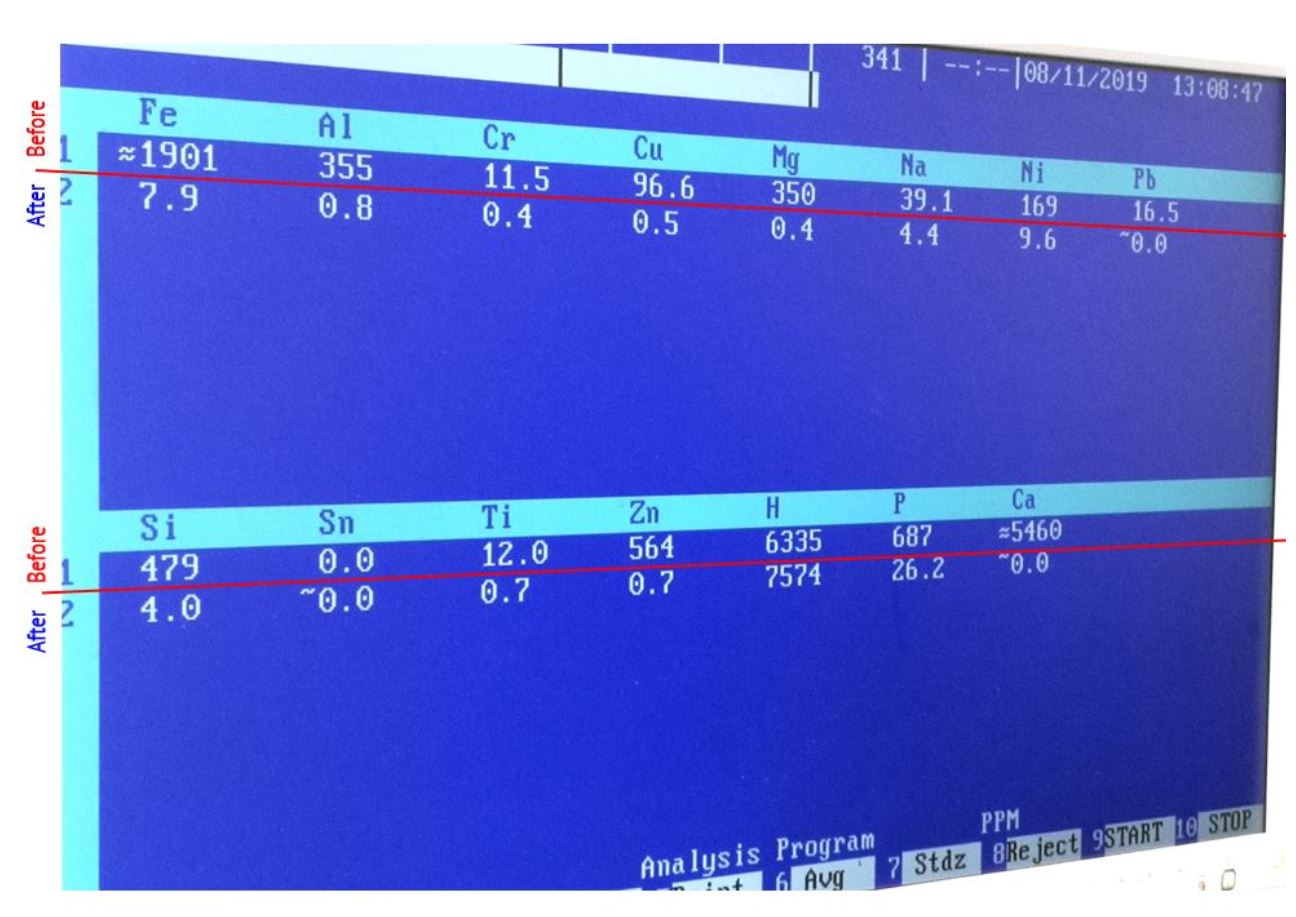

REMOVED FROM WASTE OIL:

Water

Up to:

Sediment

Up to:

Metals

Up to:

Ash

Up to:

Up to 97% of oil available in feedstock can be separated and cleaned completely to standard quality oil products for reuse as it’s original purpose.

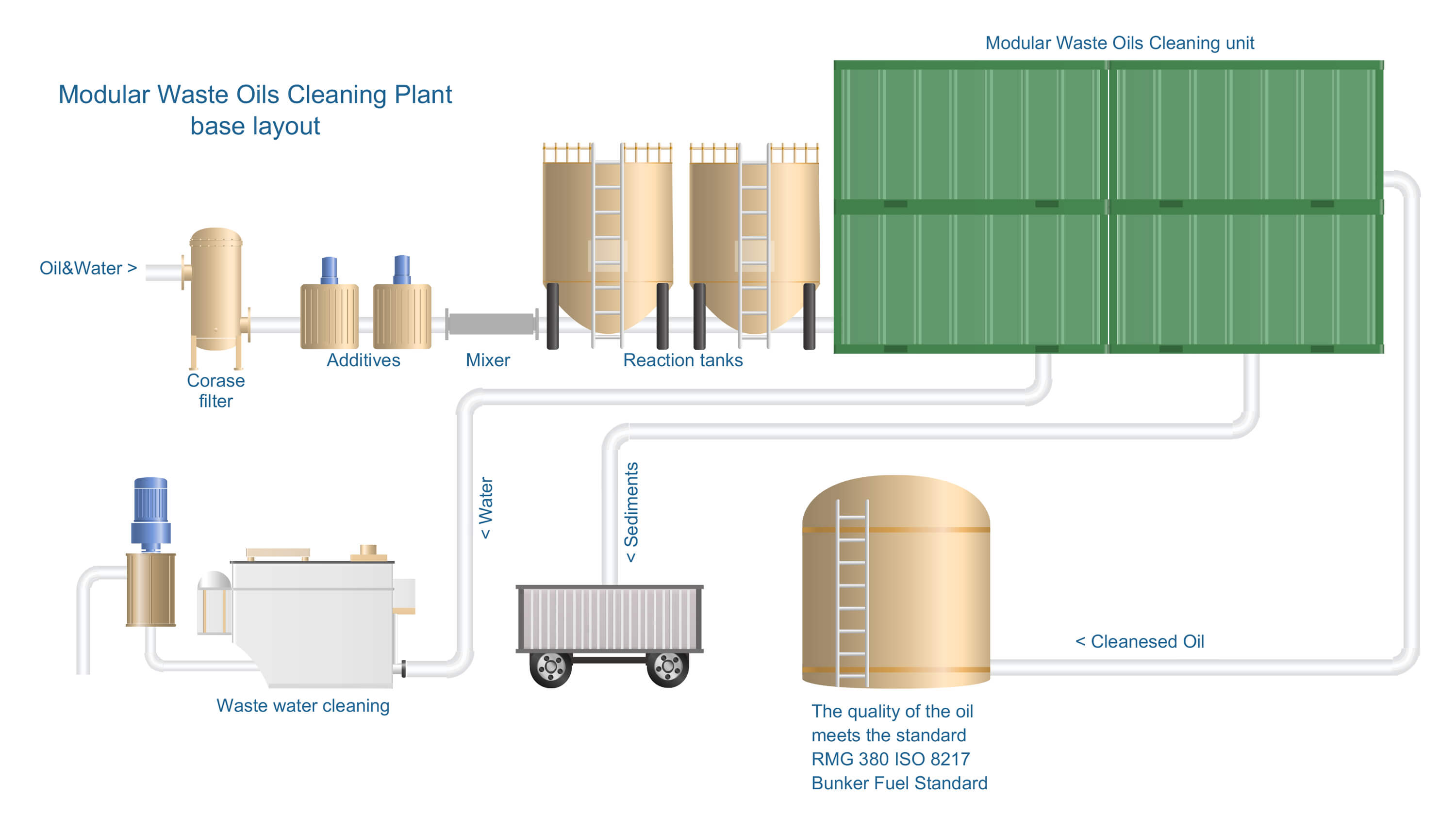

Instead of primitive processes of the sedimentation of waste oils, which to this day are used by various recycling companies, we adopt an innovative approach where such waste oil is processed in a so-called closed system without expensive refining or hydro-treatment process. In the EU Waste Directive, such wastes are listed under codes 13 01-13 05 and 16-07. Our technology ensures the optimal and efficient processing of waste oils – those oils are cleaned and recycled up to to the high quality standard oil products which can be used without attracting additional processing.

Marine slops before and after treatment

Advantages of recycling technology

Customers for recycling of marine slops,

crude sludge and used lubricating oils: